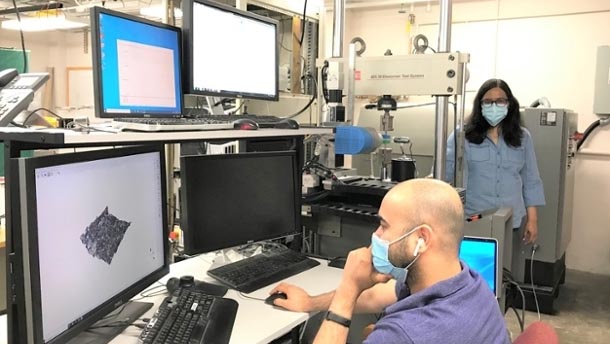

Susheel Dharmadhikari (left) and Amrita Basak (right) collaborate in the Reber building. IMAGE: PROVIDED

Grad student aims to improve structural monitoring in 3D printing

Mechanical engineering's Susheel Dharmadhikari earns AT&T Fellowship to use ultrasonic sensors, machine learning to broaden additive manufacturing

4/9/2021

By Erin Cassidy Hendrick

UNIVERSITY PARK, Pa. — Susheel Dharmadhikari, a doctoral student in the Penn State Department of Mechanical Engineering, has been awarded the 2021 AT&T Graduate Fellowship to help determine the safety and stability of additively manufactured, or 3D-printed, metal components.

“I’m trying to develop sensor-driven methods to detect fatigue,” Dharmadhikari said. “We are using principles from machine learning and statistical data mining to enhance structural health monitoring in additive manufacturing.”

Metal additive manufacturing (AM) is being explored for a multitude of applications, including large aerospace components. These components, which can range from small pieces within a gas turbine engine to the exterior casing of a rocket, need to be continually monitored for fatigue failure, or defects that occur from use, like cracks.

“Fatigue has been studied for more than 50 years,” Dharmadhikari said. “But additive manufacturing is only about two decades old. We haven’t had the chance to test 3D-printed components on the same scale as traditional metal manufacturing. By understanding some data-driven models derived from traditional materials, this project could be a pathway for using that existing information on AM fatigue, without replicating all the testing.”

As additively manufactured components become widely used, the need for materials is expected to increase as well. However, each new metal material needs to be extensively tested by engineers to gather unique data on each specific application, including how to determine whether the component exhibits signs of fatigue failure.

“Basically, we are figuring out how to be able to do non-destructive testing, while still monitoring the piece for defects,” he said. “With the current state of the technology, when you create a data-driven model, it’s done for a specific metal and a specific geometry. We want to create a framework that can work across all different geometries and materials.”

This framework could reduce the number of expensive experiments needed and provide a flexible algorithm that can be applied to any metal used for additive manufacturing.

Dharmadhikari’s project will design a testing apparatus that uses ultrasonic sensors to determine whether a type of metal has been damaged. With a machine learning algorithm in place, the method will be applied to a different type of metal to see if it can correctly determine whether cracks have occurred within the second material.

The AT&T Fellowship provides funding and recognition to outstanding graduate students conducting research with wireless data applications. The use of ultrasonic sensors, which captures wireless signals via specific soundwaves, furthers the mission of this fellowship.

Drawing on his previous experience working in industry, Dharmadhikari said he witnessed situations where this framework would be extremely helpful to 3D-printing manufacturers.

“I was aware, to some extent, of the problems that companies had when it came to additive manufacturing-related testing and analysis,” he said. “I think I know where this field might be heading, so I can visualize the impact of this research on real-world applications. It interests me how I can leverage my experience in mechanical engineering and machine learning to solve problems in this area.”

Advised by Amrita Basak, assistant professor of mechanical engineering, Dharmadhikari’s research is overseen by his committee members: Asok Ray, distinguished professor of mechanical and nuclear engineering; Chris Kube, assistant professor of engineering science and mechanics and acoustics; and Eric Marsh, the Glenn Professor of Engineering Education of Mechanical Engineering and Acoustics.

This work is also enabled through the College of Engineering’s extensive network of 3D printers and additive manufacturing research labs, including those housed in the Department of Mechanical Engineering, Center for Innovative Materials Processing Through Direct Digital Deposition, the Materials Research Institute and the Bernard M. Gordon Learning Factory.