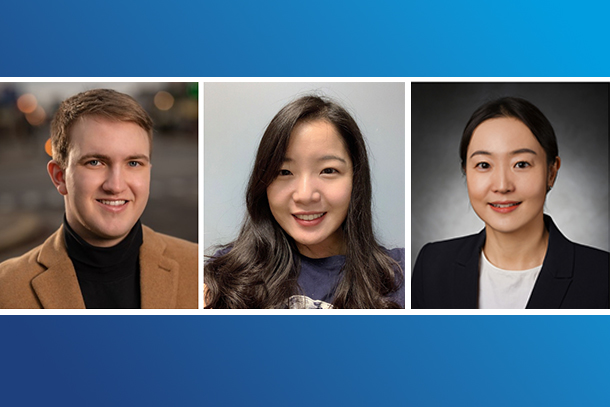

2024 Roy Award winners include, from left to right, Michael Miller, Ying Han, and Hee Jueng Oh.

Three College of Engineering researchers named 2024 Roy Award winners

Dec 3, 2024

Editor's note: This article originally appeared on Penn State News.

UNIVERSITY PARK, Pa. — Six Penn State materials researchers, including three affiliated with the College of Engineering, have received the 2024 Rustum and Della Roy Innovation in Materials Research Award, recognizing a wide range of research with societal impact. The award is presented by the Materials Research Institute (MRI) and recognizes recent interdisciplinary materials research at Penn State that yields innovative and unexpected results.

The award includes four categories: Early career faculty, non-tenure faculty, post-doctoral scholar and graduate student. It exists thanks to a gift from Della and Rustum Roy, who are both late alumni of Penn State’s College of Earth and Mineral Sciences and were long-serving faculty in the college.

This year’s winners were announced at the 2024 Materials Day event in October. The three winners affiliated with the College of Engineering include:

Michael Miller, doctoral candidate, biomedical engineering

The human gut has a thick layer of mucus covering the intestinal cells that plays host to millions of bacteria that both aid digestion and defend against infection. Miller's research focuses on creating materials that replicate the gut microbiome, including the mucus, intestinal wall and bacterial community. They use non-natural amino acids to make a gel-like substance that shares similar physical properties with native gut mucus. Using this, they can model the growth and interactivity of bacteria found in the gut and estimate how drugs move through the gut microbiome.

“A model gut microbiome like we have created is a broad benefit to studying gut health,” Miller said. “This material format improves the repeatability of studies on digestion, drug delivery to intestinal tissue, or bacterial community response to different stimuli. In the future, it can also be modulated to more accurately represent disease conditions that affect the gut microbiome. Continued work will ideally quicken the development of new therapies to improve quality of life for those with many digestive diseases and disorders.”

Ying Han, postdoctoral researcher in engineering science and mechanics

Han’s research uses powerful transmission electron microscopy to study materials at the atomic level. This tool allows Han and his team to see how the internal structure of materials changes and how those changes affect their performance. By understanding these details, they can improve the design of advanced materials, such as high-performance alloys and semiconductor devices. For example, they examine specific atomic patterns in complex alloys to make them stronger or more durable and analyze how different materials are combined in semiconductors to refine their production processes.

“Modern technological advancement demands increasingly sophisticated materials and devices with precise control down to the atomic scale,” Han said. “My research bridges fundamental materials science with practical applications, contributing to the development of stronger alloys, more efficient electronic devices and improved energy storage systems. By understanding and engineering materials at the microscopic level, we can create more durable and efficient components for next-generation electronics, energy systems and structural applications, ultimately advancing technological capabilities across multiple industries.”

Hee Jueng Oh, assistant professor of chemical engineering

Oh’s team creates advanced polymer membranes to tackle some of the world’s most critical and complex separation challenges in energy, environmental protection and health care. They design specialized polymers that are highly selective, develop innovative membrane structures that did not exist before and study how the chemical and physical properties of these materials affect the movement of molecules through them. Efficiently separating molecules supports everything from traditional industrial processes to future carbon-free technologies.

“Chemical separation is important for modern society because designing polymer membranes that can transport target molecules with high selectivity and productivity is critical for our access to clean water, air, energy, environment, food and medicine,” Oh said. “From a fundamental point of view, we study the relationship between polymer chemistry, processing, structure and transport properties for separation science. These fundamental studies are critical for designing membranes for liquid, gas and vapor separations, energy storage, resource recovery, critical element recovery, selective removal of unwanted molecules from various chemical streams, biomedical devices, controlled drug delivery and barrier materials for food and packaging.”