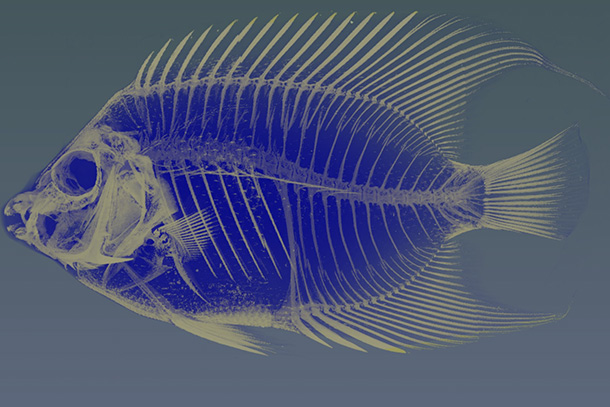

Scan of a Carribean Queen Angel Fish (Holacanthus ciliaris). The fish was scanned on the GE v|tome|xL 300 nano/microCT at 55.5 µm. Credit: Penn State.

Revealing invisible educational opportunities through CT scanning

From Penn State students to industry professionals, the Center for Quantitative Imaging provides training on CT scanning equipment, techniques and software

Sept 20, 2024

Editor's note: This article originally appeared on Penn State News.

By Kevin Sliman

UNIVERSITY PARK, Pa. — As a part of its mission to educate and train industry partners and students on computed tomography (CT) scanning, the Center for Quantitative Imaging (CQI) recently supported a three-day additive manufacturing practicum for industry professionals to gain hands-on experience in using 3D X-ray CT scanning. The center offers CT scanning, which allows users to see the internal make-up of an item as large as a grizzly bear skull to the tiny electrical connections within a smartwatch. Similar to the practicum, faculty members have regularly brought their classes to CQI to receive training and education on CT scanning equipment, techniques and software, all of which is available to faculty members and industry.

Odette Mina is the managing director of the Institute of Energy and the Environment’s laboratories, which includes CQI. She said the Center for Quantitative Imaging's comprehensive training equips participants with invaluable hands-on experience, working with cutting-edge technology, techniques and resources, enhancing their skill sets and positioning them for future success in their field.

"Our goal at CQI is to empower students with the tools they need to excel in their fields," Mina said. "By providing expert training and hands-on learning experiences, we're helping them develop the skills that will drive innovation and discovery."

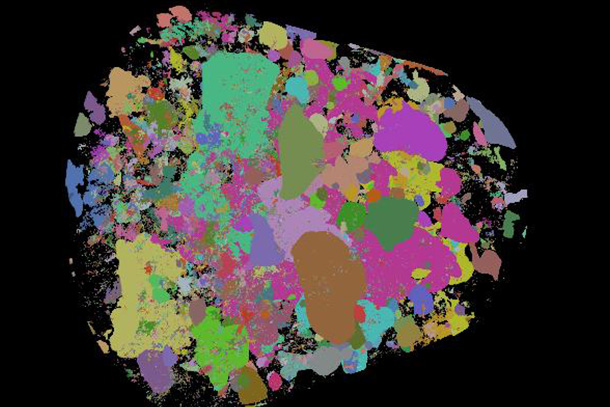

Yashar Mehmani is an assistant professor in the College of Earth and Mineral Sciences. He studies porous materials, objects with tiny holes throughout them. His research explores how those materials impact topics including subsurface energy production, CO2 storage and groundwater contamination. As an educator, Mehmani has used the expertise at CQI to expand his capability to teach about porous materials in the context of subsurface engineering applications.

“The course primarily focuses on the macroscopic description of fluid flow physics in porous media, but towards the end of the class we dig deeper into what happens at smaller scales, also known as the ‘pore scale,’” Mehmani said. “X-ray imaging is a key tool to peer into the microstructure of porous materials and to map the spatial distribution of various fluids in them. So, I wanted my students to see such equipment firsthand and be instructed by the capable staff that operate the equipment at CQI.”

Computed tomography scan of a 2.5 cm picrite core. The internal pores of the core have been identified and individually labeled by color. Credit: Michelle Quigley.

Mehmani said CQI hosted his entire class and has done so since 2021 to introduce them to the equipment at CQI.

“The CQI staff provided lectures on the general operating principles of CT scanners and scanning,” he said. “They also showed them what kind of images can be obtained from these devices and introduced them to a wide range of applications, some by researchers at Penn State. The students have always loved it.”

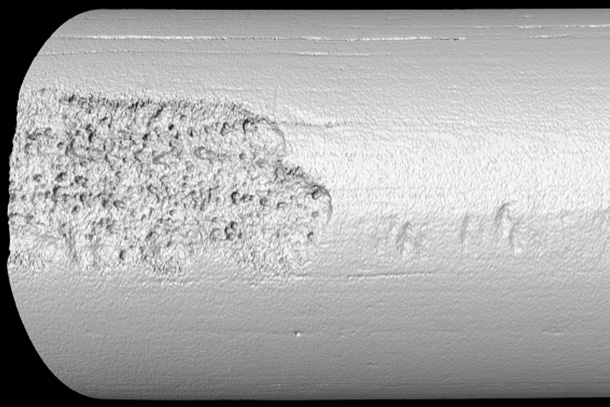

Students learning about additive manufacturing with Amrita Basak, the Shuman Early Career Professor in the College of Engineering, also gain valuable lessons from CQI. In her class, Basak teaches about software, analysis tools and imaging techniques related to hands-on aspects of additive manufacturing.

“Computed tomography is one of the most popular non-destructive testing techniques that the additive manufacturing community uses for qualifying parts,” Basak said. “CQI demonstrates how CT scans are provided, and the students were able to not only see the facility but also interact with the staff to get familiar with how they might want to scan their own research specimens.”

The Center for Quantitative Imaging created an X-ray computed tomography image from a 1.5 mm-long steel cylinder after it was exposed to a high-temperature, high-pressure aqueous solution. Credit: Derek Hall et al.

“CQI's commitment to excellence is evident in their comprehensive training programs and innovative resources,” said Guha Manogharan, the Emmert H. Bashore Faculty Development Associate Professor in Mechanical Engineering and co-director of CIMP-3D who helped organize the practicum. “Their team of experts delivers engaging and informative sessions that are designed to meet the specific needs of professionals from various industries. By combining practical knowledge with hands-on experience, they equip their clients with the tools they need to thrive in today's dynamic business environment.”

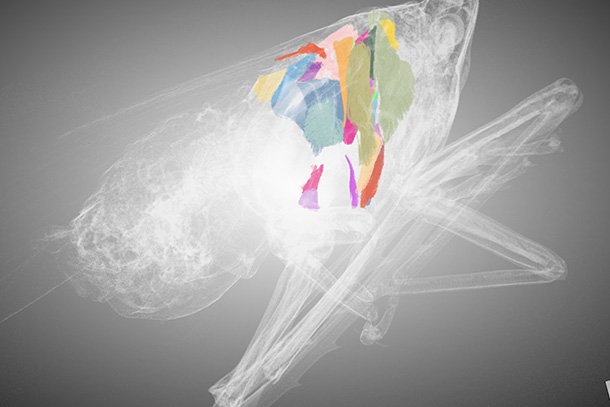

This 3D image of a spotted lanternfly female illustrates the size and position of thoracic locomotory muscles in various colors and the silhouette of the insect in light gray. Credit: Provided by Flor Acevedo.

Faculty members who would like to explore using CQI or any of the Institute of Energy and the Environment’s laboratories for educational purposes should contact Odette Mina. Similarly, industry professionals interested in IEE’s lab services or training should contact Mina.