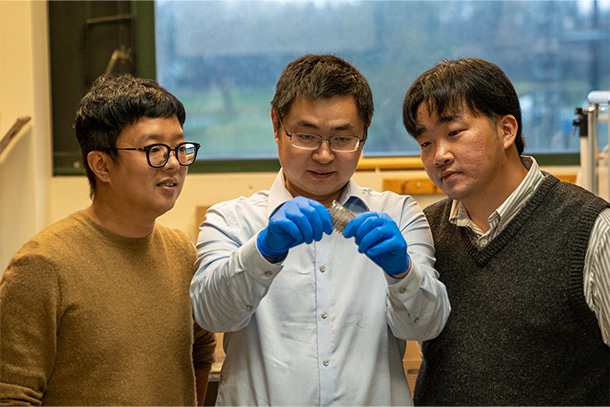

From left to right: Hyunseok Shim, postdoctoral scholar in the Penn State Department of Engineering Science and Mechanics (ESM), Cunjiang Yu, Dorothy Quiggle Career Development Associate Professor of Engineering Science and Mechanics and associate professor of biomedical engineering and of materials science and engineering, and Seonmin Jang, Penn State doctoral student in ESM, developed a fully rubbery stretchable diode that maintains performance. Credit: Jeff Xu/Penn State. All Rights Reserved.

Stretchable rubber diode opens possibilities for medical, electronic devices

November 30, 2022

By Sarah Small

UNIVERSITY PARK, Pa. — If you are reading this article on your computer or phone, it is in part thanks to diodes. Diodes — typically rigid electrical components that easily conduct electric current in one direction — are used for a variety of critical electronic functions, from converting AC to DC and converting energy from mechanical to electrical to serving as a switch component that enables digital displays and more. Electronic devices, such as robotics or medical devices, are becoming more flexible as technology advances, so Penn State researchers have developed a fully rubbery stretchable diode that maintains performance.

The team published their results in Science Advances.

“This diode is all made out of stretchy rubber materials — that rubber material strategy is the key,” said corresponding author Cunjiang Yu, Dorothy Quiggle Career Development Associate Professor of Engineering Science and Mechanics and associate professor of biomedical engineering and of materials science and engineering. His group has previously developed other rubbery electronic materials, such as transistors. “By creating a rubbery diode, we’ve enriched our library of rubbery electronics so that we can move closer to making integrated electrical circuits and systems fully out of rubbery materials.”

More flexible devices can behave more like biological tissue, allowing for better bio-integrated devices, according to Yu. An example may be a soft patch device that could be implanted on the heart.

“A heart beating will generate electric signals,” he said. “With a rubbery diode, a device could convert AC to DC within the body, which is not currently possible.”

To achieve such electrical performance while mechanically stretched, Yu said, the researchers rationally considered the device architecture, vertical structures and layout. In addition to benefits for more flexible medical devices, the development also has implications for power management systems in these medical devices toward self-sustainable systems.

“Energy scavenged from harvesters always needs to be rectified before the energy is stored for usage — and it's important in many emerging fields,” Yu said.

Yu gave the everyday example of light-up sneakers, which contain a piezoelectric energy harvester to convert mechanical energy — a step — to electrical energy to light up the LEDs. A rectifying circuit converts the harvested AC electricity into useful DC power.

“Researchers and industry are using conventional diodes, but they want something that could be stretched, like what we report in the paper,” he said. “Such rubbery diodes open up many possibilities.”

Yu said that next steps include further optimizing the diode and integrating it into more complex systems.

“We're looking to improve the diode architectures and performances and to achieve unperturbed operations even under very large extents of mechanical stretch or deformation,” he said. “We want to use these diodes to address critical device needs in various emerging applications such as robotics and biomedical devices."

Seonmin Jang and Hyunseok Shim, both of the Department of Engineering Science and Mechanics at Penn State, were also authors of this paper. The Office of Naval Research and the National Science Foundation funded this research.