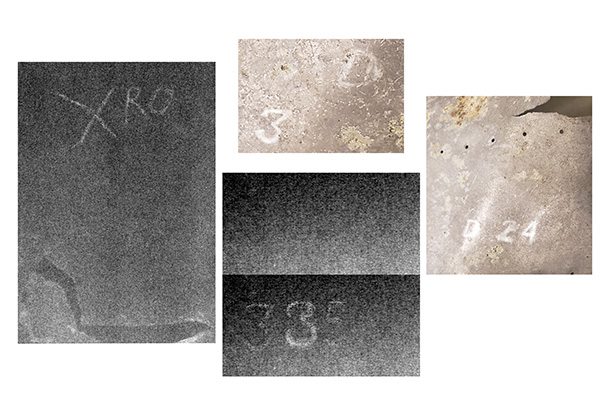

The aluminum panel was found on a small pacific island close to where Amelia Earhart and her navigator, Fred Noonan, last made radio contact. Overlaid on the panel are the neutron radiography results, revealing information not visible to the naked eye. Credit: Provided by Kenan Ünlü . All Rights Reserved.

How the Amelia Earhart mystery may inform microplastics research

Upgraded facility at Penn State’s Breazeale Nuclear Reactor reveals old information and exposes contemporary challenges

November 29, 2022

By Ashley WennersHerron

UNIVERSITY PARK, Pa. — The aluminum panel is dull, corroded and covered in a patina of scratches from tumbling around the Pacific Ocean, likely for decades, before washing up on the small atoll of Nikumaroro. Parallel rivet lines puncture the panel, similar to the ones that dotted the Lockheed Electra Amelia Earhart flew on her ill-fated round-the-world trip in 1937, but they’re not a precise match. It is possible that the panel was a retrofit — a patch to replace a rear window — but with only 85-year-old photos to compare, the theory is difficult to investigate beyond reference measurements.

But it’s not impossible, especially with neutron radiography. The non-destructive imaging technique can peer beyond the veneer of age and damage to spy the tiniest of clues. It can also ferret out mere hints of contaminants, including pervasive pollutants.

Daniel Beck, engineering program manager in Penn State’s Radiation Science & Engineering Center (RSEC), first connected with Richard “Ric” Gillespie, who found the panel in 1991 and leads The International Group for Historic Aircraft Recovery (TIGHAR), after watching the 2019 National Geographic documentary “Expedition Amelia.” Beck thought that, with help from the Penn State Breazeale Reactor, the RSEC team might be able to determine if there was anything hidden on the panel.

“We thought it was a good fit — we were fairly confident we’d be able to see the remnants of marks worn away or paint particles,” Beck said. “The first images were really exciting, but we knew we needed to do better to confirm what we thought we saw. We were already in the process of upgrading the neutron imaging facility, so the panel provided the perfect sample to optimize our neutron radiography capabilities.”

Neutron radiography involves irradiating a sample — the panel, in this case — with neutrons. The neutrons pass through heavier particles and interact with some of nuclei of lighter particles in the sample. A digital imaging plate captures the contrasts as neutrons exit the sample on the other side, creating a screen print of the sample’s image, including information not visible to the naked eye.

After upgrading the neutron imaging facility and refining their techniques over the last year, the researchers completed a final analysis of the panel. They observed something new.

Neutron radiography revealed several characters in the panel. Clockwise from left, the characters read: XRO, 3D, D24 and 335 or 385. Credit: Provided by Kenan Ünlü. All Rights Reserved.

“We found what looks like stamped or painted marks that could be from the original manufacturer,” said Kenan Ünlü, director of RSEC and professor of nuclear engineering. “D24 and 335, or maybe 385. We don’t know what they mean, but they are the first new information from this panel that has been examined by various experts with different scientific techniques for over 30 years.”

Gillespie is now consulting with forensic analysts to decipher the six characters and what they might represent. If they can conclusively determine what the marks mean, such as a production number, it could confirm the panel came from Earhart’s plane. It could also definitively rule out the possibility.

“My mission — the mission of TIGHAR — is to use science to help solve aviation mysteries,” Gillespie said. “Whether this information provides more evidence or disproves that the panel belonged to Earhart’s plane, I’ll be glad to know.”

It’s not the end of the story for the aluminum panel and certainly not for the RSEC neutron imaging facility, according to Ünlü.

“We refined the facility with this old panel as a sample, and now we’re applying the technique to a far more contemporary challenge: distribution of microplastics in environment,” Ünlü said.

Microplastics — the particles that remain as plastic products break down — are ubiquitous across the planet and classified as an “emerging pollutant,” according to the National Center for Environmental Health and the Agency for Toxic Substances and Disease Registry. Despite their prevalence, little is understood about how they disperse and their effects, Ünlü said.

Alibek Kenges, a doctoral student in nuclear engineering at Penn State, is part of the RSEC team and is now leading the efforts to visualize microplastics with neutron radiography and tomography as his dissertation project.

“Microplastics are everywhere, in sand, soil, water, etcetera — we’re trying to figure out how they get there,” Kenges said. “First, we examined scoops of sand to keep the samples as close to as in situ as possible. The neutron imaging technique works perfectly: the resulting image doesn’t show the sand at all, but the microplastics, from a millimeter to a few millimeters in size, light up like Christmas lights.”

Buoyed by the success of that test, Kenges is now examining different types of filtration materials used to sieve microplastics from water samples. He found that the neutron imaging approach could potentially be used to detect microplastics in the water filters, but the technique needs refinement to account for uncertainties related to parts of the imaging system.

“Now, we’re performing controlled experiments, where we already know the microplastic content and type, to establish the detection limits of our system and to fine-tune the methodology,” Kenges said.

Neutron radiography can also help identify microplastics in samples. The bright red specks are microplastics, and the red discs are filters. Credit: Provided by Kenan Ünlü/Penn State.

Ünlü recently presented the preliminary microplastics results at the International Atomic Energy Agency’s 2nd International Conference on Applications of Radiation Science and Technology in Vienna, Austria, at the end of August.

“We hope that visualization of microplastics in environmental samples will help to inform approaches to solve this global problem,” Ünlü said.

The applications are far reaching, Beck said.

“We started by revealing a potential clue for a mystery almost a century old, which pushed us to optimize the imaging facility at RSEC,” Beck said. “Now we’re learning new information about something that will impact generations to come.”