Hui Yang and Soundar Kumara have developed a novel algorithm, which has implications for health care and manufacturing. IMAGE: HUI YANG AND SOUNDAR KUMARA

New method analyzes images to improve health care and manufacturing

5/20/2020

UNIVERSITY PARK, Pa. — Patterns appear in both natural and human made systems, but they can be difficult for humans to recognize and analyze, especially in dynamic systems like the human heart or factory machines. To address this issue, researchers in the Penn State College of Engineering have developed a novel algorithm, which has implications for health care and manufacturing.

The researchers focused on understanding patterns in nonlinear, dynamic systems, as these intricate systems are challenging to analyze due to their nature — they fluctuate over multiple dimensions, such as space and time, and are near impossible to understand via human observation.

Led by Hui Yang, Harold and Inge Marcus Career Associate Professor, Soundar Kumara, Allen E. Pearce and Allen M. Pearce Professor of Industrial Engineering, and Cheng-Bang Chen, lecturer in the Harold and Inge Marcus Department of Industrial and Manufacturing Engineering, the methodology was published in the American Institute of Physics Chaos Journal.

“Our methodology analyzes different kinds of recurrences in data to provide a better understanding of the world around us,” Yang said. “This work allows us to build a bridge between biological patterns, like in human anatomy, and man-made patterns, like in manufacturing.”

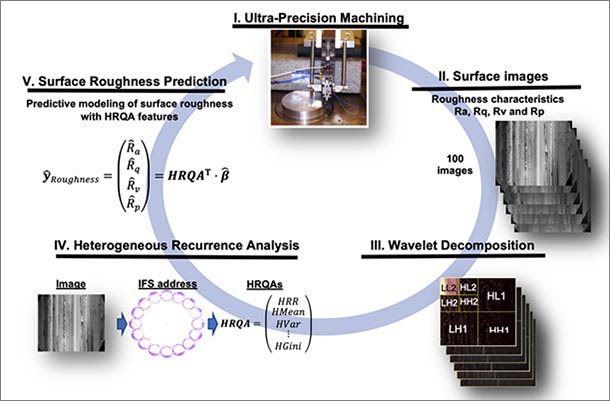

To create the novel algorithm, the team analyzed spatial data in complex, microscopic images produced by ultra-precision machining. UPM, a manufacturing process that uses single-crystal diamond tools to refine metal workpieces at the atomic scale, is widely used in modern industries such as semiconductors and aerospace to produce highly precise cuts or polishing.

The spatial data showed a variety of surfaces over the UPM images, ranging from flat to rough to severely rugged. Good, quality products should have a similar surface, and bad quality products might have different textures on the surface.

This operation captured and reiterated the behaviors of recurrence variations in the spatial data from the images to represent, characterize and quantify spatial patterns in the UPM images. The surface characteristics were shown to be highly correlated with the spatial recurrence patterns within the imaging data.

According to Chen, in the past, researchers had to physically measure a piece to get the quality of surface finishes when manufacturing. Their work now allows surface roughness to be approximated by using the images, which ultimately leads to cost savings and resource conservation.

In the future, this methodology can improve predictive models for the quality of UPM surface finishes to enhance the quality of manufacturing.

“The algorithm teaches you new things about the system as a whole,” Kumara said. “Take for example: a signal impulse happens in one part of a system at a given time and space. Later, it has an observed repetition at a different point in time and space. If that pattern is found, then you can use it to predict such behaviors in the future.”

According to Yang, the algorithm has broad implications for medical applications such as monitoring organ function, analyzing cancer images, and detecting organ dysfunction over time.

“You can use this algorithm on complex-structured data that is measurable or observable and is represented in 2D, 3D, or high-dimensional images,” Yang said.

The National Science Foundation, the Allen E. and Allen M. Pearce Endowment and the Harold and Inge Marcus Department of Industrial and Manufacturing Engineering, Penn State supported this work.