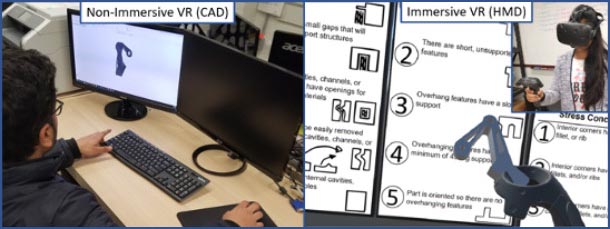

Researchers in the College of Engineering will investigate how virtual reality (right) may be used instead of traditional computer-aided design software (left) to introduce and teach additive manufacturing to undergraduate engineering students. IMAGE: PROVIDED BY NICHOLAS MEISEL

Putting reality in virtual additive manufacturing education

National Science Foundation awards engineering research team funding to investigate virtual reality additive manufacturing learning for undergraduate students

11/16/2020

By Samantha Chavanic

UNIVERSITY PARK, Pa. — As the engineering industry evolves, so must the education of future engineers. Advances in additive manufacturing (AM), or 3D printing, continue to propel engineering sectors toward innovative production capabilities, but access to cutting-edge machinery isn’t always available to undergraduate engineering students. This lack of access, whether due to remote learning or availability of machines, leads to academics searching for unique ways to bring these new additive technologies and opportunities to students.

A team of Penn State researchers recently received funding from the National Science Foundation to investigate how virtual reality (VR) may be applied to introduce and teach AM to undergraduate engineering students when access to physical machines isn’t an option. Led by principal investigator (PI) Nicholas Meisel, assistant professor of engineering design and mechanical engineering, the three-year, $300,000 grant will examine how virtual simulations can help undergraduate engineering students better understand how AM processes work and how to properly design parts for AM production. Scarlett Miller, director of the School of Engineering Design, Technology, and Professional Program’s engineering design program and associate professor of engineering design and industrial engineering, and Timothy Simpson, Paul Morrow Professor of Engineering Design and Manufacturing in the College of Engineering, serve as co-principal investigators on the project.

“Beyond common desktop 3D printers for plastics, high-end AM systems for metals are incredibly complex and expensive, which makes it difficult for students to get exposure to them during undergraduate studies,” Meisel said. “This makes it difficult for them to both learn how the process works, as well as how to design parts that can be successfully printed. Additionally, AM is capable of producing incredibly complex geometries, which can make it difficult for students to be able to model and visualize these geometries using traditional [computer-aided design].”

Meisel explained that computer-aided design (CAD) programs aren’t designed to handle the geometric complexity that AM can achieve, meaning, for the first time in history, the ability to manufacture complex parts has outpaced the ability to design them.

Enter virtual reality.

“AM and virtual reality are both transformative technologies,” Meisel said. “While both still seem like something out of science fiction in some regards, the reality is that both have significant potential to change the way that engineers design and manufacture products. Because of this, I think it’s incredibly important for students to be exposed to them early in their education.”

The researchers will study how visual immersion and process complexity affect a student’s cognitive load, or the amount of information working memory can hold at one time, while learning an AM system and assessing AM designs. The research team will recruit undergraduate students from various engineering design, mechanical engineering and additive manufacturing courses for immersive 3D printing experiences.

As a leader in AM research and education, Meisel said Penn State is uniquely situated to complete this project, as it maintains all seven AM process types on campus. Access to this machinery allows for endless control experimentation with the physical systems.

“Penn State is currently at the forefront of AM education across the country,” he said. “Right now, I think we’re setting the example that other top-tier universities are trying to emulate, not only in undergraduate education but also in our unique additive manufacturing and design master’s program as well as faculty mentorship and student involvement in AM research.”

The researchers hypothesize that virtual reality’s immersive nature will lessen a student’s cognitive load, filtering out needless tasks associated with current CAD systems and improving AM education and design.

“The outcomes of the research will hopefully be the identification of significant learning differences when using VR to understand different AM process types like desktop material extrusion versus industrial powder-bed fusion, quantitative evidence of the impact of VR on student cognitive workload during AM design evaluation and an understanding of the viability of integrating VR into a student’s engineering design process to support process-specific DfAM [design for additive manufacturing] education,” Meisel said.