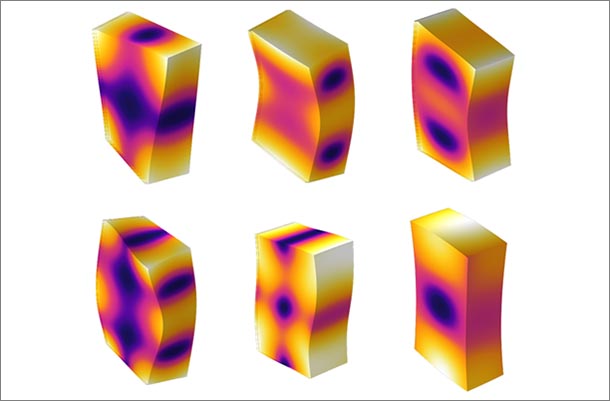

As part of the 2020 AFRL SFFP at AFRL-Materials and Manufacturing, Chris Kube, assistant professor of engineering science and mechanics, and Jared Gillespie, graduate student in engineering science and mechanics, conducted research that focused on the influence of texture and residual stress on the measurement of vibrational resonances of metallic additively manufactured parts. The simulated natural vibrational modes seen here give important insight into the properties of additively manufactured parts. IMAGE: MATTHEW CHERRY, AFRL

Engineering professor uses AFRL fellowship to research additive manufacturing

9/23/2020

By Tessa M. Woodring

UNIVERSITY PARK, Pa. — For 12 weeks over the summer, Christopher Kube, assistant professor of engineering science and mechanics in the Penn State College of Engineering, conducted research as part of the 2020 U.S. Air Force Research Lab (AFRL) Summer Faculty Fellowship Program (SFFP) at AFRL-Materials and Manufacturing. Kube was named a fellow of this program in March of this year.

According to the AFRL website, this eight- to 12-week program offers participating fellows hands-on experience with Air Force research challenges and aims to enhance the research interests and capabilities of the fellows. Participants have the opportunity to conduct research at AFRL Directorates, the Air Force Test Center, the United States Air Force Academy or the Air Force Institute of Technology.

While participating in this program, Kube collaborated with Jared Gillespie, graduate student in engineering science and mechanics, to conduct research that was focused on the influence of texture and residual stress on the measurement of vibrational resonances of metallic additively manufactured parts.

Kube and Gillespie originally planned to conduct the research at the Wright-Patterson Air Force Base in Dayton, Ohio. However, the technical sponsors of their project allowed them to work remotely to avoid traveling during the pandemic.

“We were extremely grateful to have such an opportunity to conduct exciting research under the circumstances this past summer,” Kube said.

Kube explained that the vibrational resonances he studies can be compared to the vibration heard or seen when observing a tuning fork. His research looks at how undesirable factors such as texture and residual stress influence how additively manufactured parts “ring” or vibrate.

According to Kube, the results from his research are aimed at improving the quality and performance traits of additively manufactured parts that are used to advance the sustainability of aircraft systems.

“Ultimately, we hope to use the modeling to further develop a vibrational method able to ensure the additively manufactured part has the exact properties as desired for its intended application, for example, as parts in jet engines,” Kube said.

Through the AFRL SFFP, not only did Kube have the opportunity to further advance his research, but the collaboration between Kube and Gillespie also helped Gillespie gain valuable experience with computational simulations. Gillespie will continue to advance the computational models during the fall 2020 semester with support from AFRL and the Southwestern Ohio Council for Higher Education.

“The highlight of the program was seeing Jared’s progress under the circumstances,” Kube said. “Because of his efforts, our collaborative team has a completely new computational capability that will allow us to look at additively manufactured parts of all shapes, sizes and complexity.”