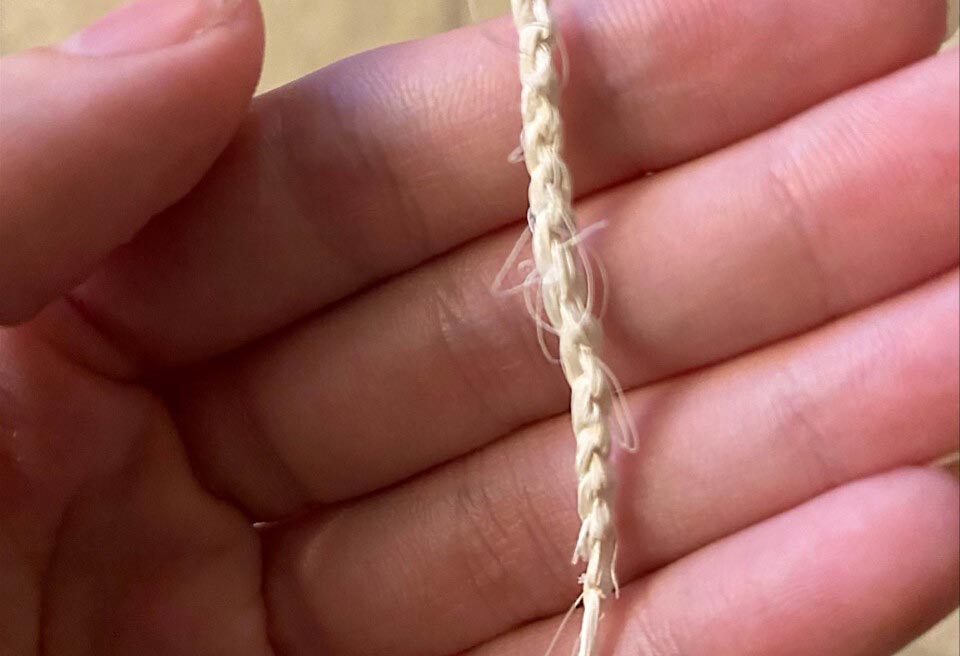

Ally Bythell, a 2021 Penn State graduate who earned her bachelor of science in biomedical engineering and mechanical engineering, crocheted the world's first example of yarn made from Squitex fiber. IMAGE: ALLY BYTHELL/PENN STATE

From waste to wear: How squid may be key to material revolution

7/26/2021

By Ashley J. WennersHerron

UNIVERSITY PARK, Pa. — With elongated bodies, large eyes and a combination of arms and tentacles, squid appear alien. In reality, they are one of the oldest classes of animals on the planet. Squid evolved during the Jurassic period and now appear in every ocean around the world. They are ubiquitous across literature and cuisine alike, popping up in stories and on plates since at least the fourth century B.C., when Aristotle first described the beasts in “The History of Animals.”

Now, nearly two and a half millennia later, squid may be the answer to a modern dilemma — plastic pollution. Melik Demirel, Penn State Lloyd and Dorothy Huck Chair Professor in Biomimetic Materials and professor of engineering science and mechanics, leads a research team investigating how to mimic nature in an effort to mitigate damage caused by humans.

“Can we create naturally resourced material to replace existing synthetic fibers?” Demirel asked. “Yes. Using squid protein, we can produce fibers that are mechanically robust, biodegradable, breathable and self-healing.”

Demirel launched his research project a decade ago, focusing on the sharp, circular teeth found in the suction cups of squid tentacles. These ring teeth help squid hold onto their prey. They are durable, flexible structures that can heal themselves without losing strength or function. The teeth’s proteins are responsible for this evolutionary benefit, but since they contain so few, Demirel said, it is not worth attempting to harvest directly from the squid. Instead, his team introduced the proteins to E. coli bacteria, which can perpetually reproduce the proteins in significantly greater quantities.

“The squid ring teeth proteins are similar to silk, like that made by spiders, but they evolved in water,” Demirel said, noting that spider silk tends to shrink in water.

The researchers ferment the proteins using sugar, water and oxygen. The resulting mash is dried into a powder, which is processed through a wet spinner, which sprays out strands of water containing the powder. The wet spinner spins, twisting the strands into a fiber the researchers augment with either acrylic or cellulose to enhance their recyclability, according to Demirel. The result is a composite fiber Demirel calls Squitex.

Squitex fiber production via wet-spinning: Lab-produced video on the Squitex fiber production process. VIDEO: M.C. DEMERIL LAB

The proteins are made of amino acids that repel each other and slip apart at the atomic scale, producing unusual tangles of biological material — which, in turn, can be manipulated into flexible, biodegradable fiber strong enough to lift 3,000 times its own weight. In 2020, Demirel co-authored a Nature Materials paper on the proteins.

“Nature took 350 million years for squid to evolve this material,” Demirel said. “In 10 years, we’ve taken it from genes to powder to wet spinning. Now, one of our students has produced the first example of this type of yarn in the world.”

Ally Bythell, a 2021 Penn State graduate who earned her bachelor of science in biomedical engineering and mechanical engineering, has crocheted since she was eight years old. Demirel’s work stood out as Bythell searched for a senior capstone design project, during which she would need to apply her engineering training to a real-world project. She led the senior team funded by the Penn State Studio for Sustainability and Social Action and focused on producing textiles from Squitex. The team members all graduated from Penn State in 2021 with undergraduate degrees in the following majors: Emily Grimes, materials science and engineering; Carlos Abarca, mechanical engineering; Owen Tyndall, mechanical engineering; Kelli Wozniak, mechanical engineering; Yong Kyoung, materials science and engineering; and Tarrin Goldberg, biomedical engineering.

“I’m generally interested in art-meets-engineering projects,” Bythell said. “The end goal for this project is to commercially produce fully sustainable and recyclable materials for clothing. For us, step one was trying to create something on the small scale — could we make yarn?”

Approaching this project during the remote learning period proved even more challenging than expected. Bythell filled her home bathtub with hot water and soaked Squitex procured from the lab. She used a hook to crochet about an inch-long chain of the fiber while it was still wet.

“I wasn’t really expecting it to hold up,” Bythell said. “It took about three days to dry, and I found that the chaining actually made the Squitex even stronger.”

The process is currently expensive and slow, according to Demirel, but the potential is limitless.

“This has demonstrated that we can make chemicals from a bio-based economy, and the applications are immense,” Demirel said. “And, of course, the process is circular: The squid protein-based materials can be made from carbon dioxide-absorbing organisms, so they are not only biodegradable, but they help mitigate carbon emissions. We’re going step by step, but we want to accelerate the process. To go from genes to yarn in 10 years, we expect the next 10 years to result in even greater steps forward.”

Other contributors to Demirel’s lab and the Squitex work include Burcu Dursun, postdoctoral fellow, who wet spins the fibers, and Tarek Mazeed, postdoctoral fellow, who produces the proteins through fermentation.

Other authors on the 2020 paper on the proteins include Huihun Jung, postdoctoral fellow in Demirel’s lab; Abdon Pena-Francesch, assistant professor at the University of Michigan who conducted doctoral research in Demirel’s laboratory. At the time of publication, Pena-Francesch was conducting research in the Physical Intelligence Department of the Max Planck Institute for Intelligent Systems in Germany with paper co-author Metin Sitti, also with the School of Medicine and School of Engineering at Koç University in Turkey.